Technical Resources

Design Assistance

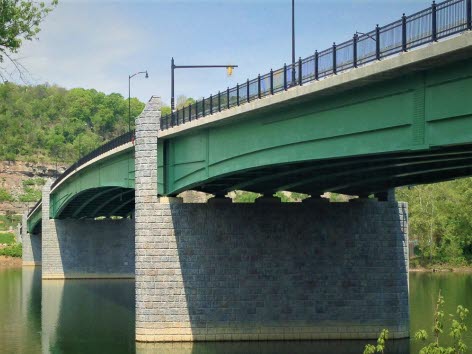

High Steel's engineering staff routinely assists the industry by reviewing structural steel designs and making suggestions to cut fabrication and shipping costs. This value-added service is useful to consultants during the design phase of the project. It also is useful to contractors as they consider developing alternate superstructure designs during the construction bidding process.

We also work with project teams on projects using design-build and Public Private Partnership delivery methods. Reach out to our team by submitting your project information and questions via our convenient form, or call our sales department anytime.

FAQ - Popular design questions

How can designers reduce shipping costs for girders?

Structural members with lengths up to 125’ long, 8’ in depth, up to 12’ in width and weighing up to approximately 40 tons can be delivered economically in most areas. As the overall dimensions increase, the incremental freight costs can dramatically rise if normal permitting limits are exceeded.

The maximum allowable shipping dimensions will vary greatly based on the geographical location where the steel is to be delivered and factors such as road conditions, access, bridge analysis, overhead clearances, and turning radius. Contact us for answers about your unique project's maximum shipping dimensions.

What is the best resource for design engineers that will ensure efficient and economical plate girder design?

We recommend using "Guidelines to Design for Constructability and Fabrication, 4th Edition, G12.1-2020" which is available for free download from the AASHTO Store.

What specifications are available for bridge steel coatings?

Remember, uncoated Weathering steel is the most cost-effective coating system for bridge steel. Owner requirements and site locations should be explored to determine if uncoated Weathering steel is permitted.

The 3 most commonly applied coating systems are:

- Traditional, zinc-rich, shop-applied paint systems are the most common.

S8.1-2014 GUIDE SPECIFICATION FOR APPLICATION OF COATING SYSTEMS - Hot-dip galvanizing is commonly used as an effective coating for smaller bridges.

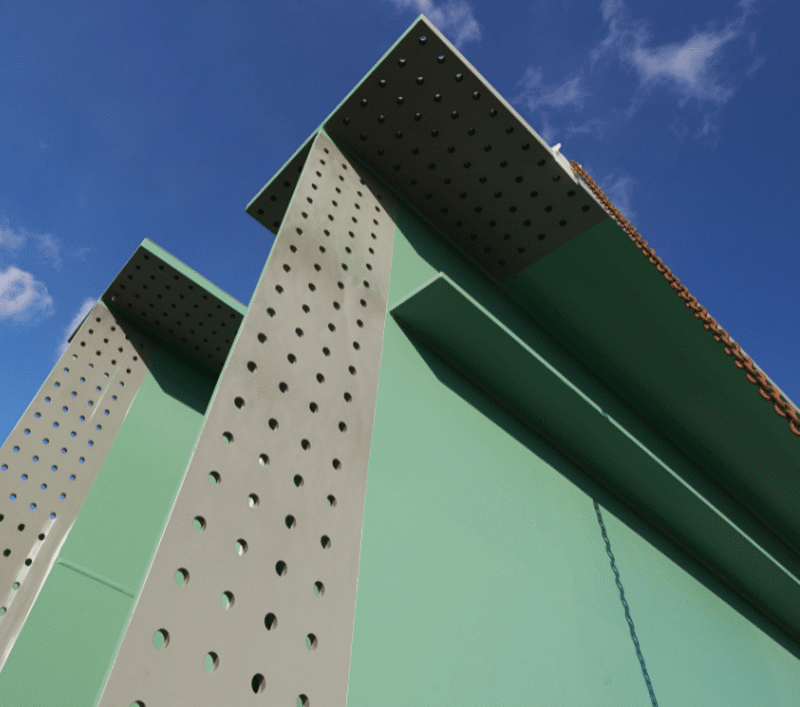

- Thermal Spray (metalizing) has become very common in recent years.

Metalizing is an effective coating for large structural members and is typically applied by fabricators in the shop.

S8.2-2017 SPECIFICATION FOR APPLICATION OF THERMAL SPRAY COATINGS FOR STEEL BRIDGES

Learn more about corrosion resistance

How can I get a budgetary price for bridge steel?

The best way to get an accurate budgetary price for bridge steel is to contact a fabricator whose market area includes the project location. Fabricators can provide an up-to-date price per pound based on the characteristics of your steel design.

Request steel budget pricing for your bridge project from High Steel.

Featured Publications

AASHTO / NSBA Steel Bridge Collaboration: G14.2-2023 Guidelines for Field Repairs and Retrofits of Steel Bridges

G14.2-2023 provides guidance and strategies related to the most common forms of damage in steel bridges and options for repair.

Additional Resources

- G9.1-2022 Steel Bridge Bearing Guidelines

- G14.1-2021 Addressing Fatigue Cracking and Details at Risk of Constraint-Induced Fracture

- G12.1-2020 Guidelines to Design for Constructability & Fabrication

- G13.1-2019 Guidelines for Steel Girder Bridge Analysis

- View All AASHTO / NSBA Steel Bridge Collaboration Documents

Questions about your project?

Do you have questions about best practices in steel bridge design for fabrication?

Need assistance with budget pricing, erecting, or shipping your structural steel?

Reach out to High Steel's experts - we look forward to helping you.